Novosibirsk (Russia): A gemstone manufacturer in Novosibirsk, Russia has managed to develop gems that they claim can even mislead professional gemmologists into thinking they're natural.

The research facility which is run by Tairus, a synthetic gemstone manufacturer, develops synthetic emeralds, and the idea behind the process is to recreate the natural look.

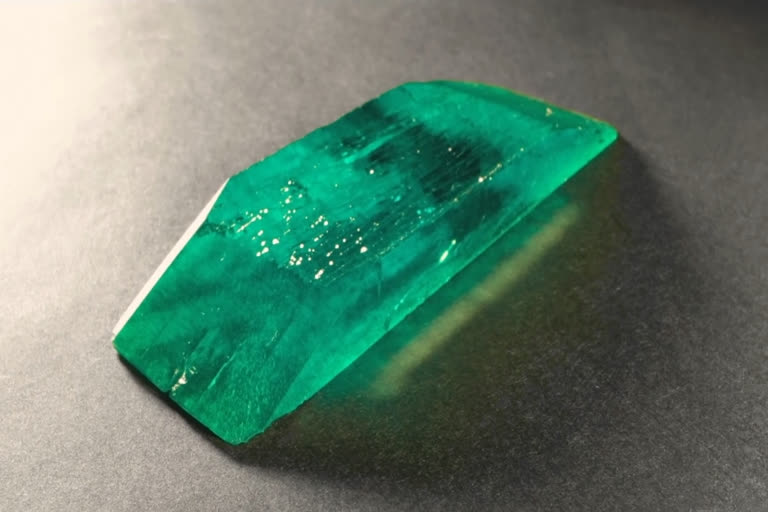

The so-called Colombian emerald is one of the favourites on show, and is a vibrant green, as close in colour as possible to the emerald that is mined in Colombia.

"This is the Colombian emerald - this is beryl dyed with vanadium. It has a very transparent structure and reflects light very well. And it has a pure colour, so the intensity of its colour practically does not depend on its thickness," says Chief Technologist of the Siberian manufacturer of the synthetic emeralds Tairus, Dmitry Fursenko.

No other manufacturer in the world has managed to achieve such transparency claim the developers.

"These are unique crystals, and no one can reproduce them. At least not yet," says Fursenko.

Rock beryl, an inexpensive and rather nondescript material, is used to manufacture the artificial emeralds. Emerald is a green variety of the mineral beryl.

Beryl is crushed and poured into special containers known as autoclaves, where at a high temperature and pressure, beryl dissolves and emerald crystals are formed, which are deposited on special plates.

Such a method is called the hydrothermal method.

Also read: Scientists develop sensor to detect chemicals used in high-energy explosives

"We call these containers autoclaves, because at high temperatures and when filled with water, they generate high pressure, like in a pressure cooker, only the temperature is lower in the pressure cooker, and the pressure is lower, but it is also high enough. And here at 600 degrees (Centigrade), one and a half thousand atmospheres are obtained," explains Fursenko.

The beryl charge is diluted with a special chemical solution, it is its composition that is one of the key factors that determine how high a quality the crystal will be.

"The composition of the solutions is our know-how, even our solutions for traditional emeralds, our concentrations, temperatures, temperature changes, and so on, everything that characterizes our process, everything that we have selected, and the quality of the charge, there are many nuances, all this together gives our high yield, so this too is not subject to disclosure," says Fursenko.

This method currently used is based on what was first developed in the Soviet Union by the scientists of the Institute of Geology and Geophysics in the 1970s and early 1980s, when Fursenko was a student and part of the research group.

It became a real revolution in its field.

It was so quickly spread that developing artificial emeralds was no longer a problem, the only problem was growing high-quality ones.

The breakthrough, among other things, consisted in a significant reduction in the cost of the process, because an alternative to the method was – and still is - the use of noble metals.

"It turned out a unique method because the emeralds grew in an autoclave made of heat-resistant steel, there was no need to make any lining of noble metals, it included very little iron, which spoils the colour very much, therefore, I believe that this was one of the outstanding developments in the field crystal growth in the Soviet Union," says scientist-geologist and geochemist Vladislav Shatskiy.

Also read: Oldest human footprints in North America found in New Mexico

In 1989, on the basis of the Institute, the Tairus enterprise was created, which continued to improve the technologies, and at the moment is the world leader in the research and production of hydro thermally grown emerald crystals.

It takes about one month to develop a stone weighing from 600 to 1,000 grams.

After which it is taken out, separated from the plates, washed several times in special solution and dried.

According to the company, the quality achieved can mislead even professional gemmologists.

In the early stages, the company even received expert opinions that their stones were natural emeralds from an unknown deposit.

"Some inexperienced gemmologists simply issue a certificate that this is a natural material, they cannot find differences, but we are not proud of this, we say that we have come so close to nature that all the differences have already been erased, although, of course, we sell everything only as (synthetically) grown stones, but their characteristics are very close to nature," says General Director of the Tairus company, Oleg Kholdeev.

The faceted (cut and polished) stones are successfully encrusted in rings, earrings, bracelets, pendants and even crowns.

"The product is successful, the geography of sales is very extensive, this is the domestic market of Russia, we also supply to the countries of Asia, America, to various European countries, we have clients all over the world," says Artemiy Khlebnikov, Head of Sales at Tairus company.

Also read: Climate change could impact algae from Arctic to Antarctic: Study

Using a similar method, they learned to grow rubies, sapphires and alexandrite, as well as red beryl - rare stones that are naturally mined only in the American state of Utah and nowhere else.

More stones are currently in development.

AP